Seafood is not only tasty, it is very healthy

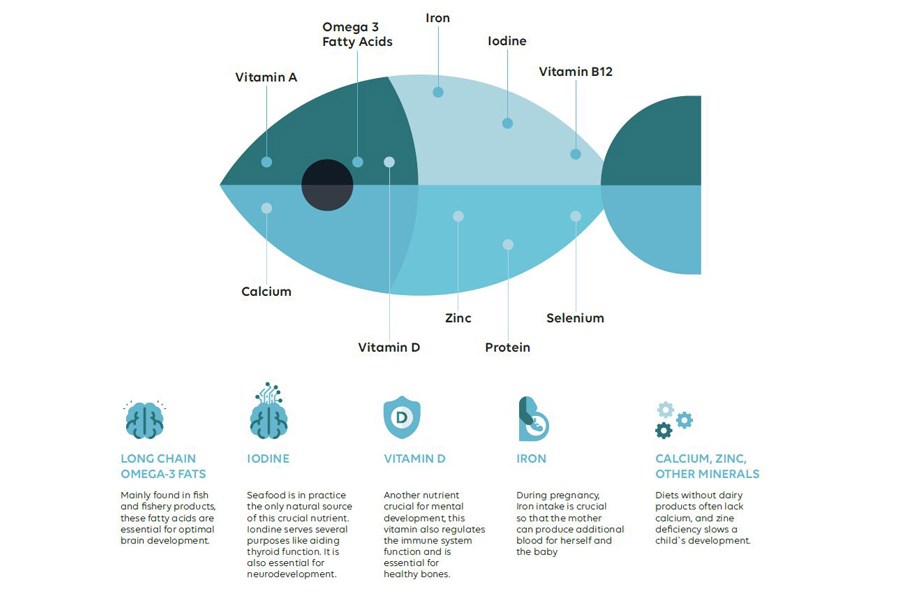

Fish is a vital source of food for people, and provides mankind with a unique combination of high-quality protein and vital nutrients. This makes fish an invaluable food. One of the major advantages with salmon and trout is their high level of the essential Omega-3 fatty acids EPA and DHA.

Omega-3 is essential for human health, and cannot be produced in the body. Thus, you must get them from your diet. Fatty fish is a great source of Omega-3. For our farmed fish, Lerøy has chosen to have an increased level of Omega-3 in the feed, through sustainably produced microalgae. This gives our fish an increased level of Omega-3.

Through our value chain, we not only deliver more than 5 million seafood meals every day, we also secure the best quality and the highest level of food security. Through our system of extended tracking, we provide full traceability from roe to table for our farmed fish, and from fjord to table for our wild catches.

At the end of our value chain, we are systematically developing easy-to-make healthy products in order to contribute to improved public health.

The Group’s products are distributed on the Norwegian market and more than 80 other markets worldwide. In order to provide a good consumer experience and ensure minimum waste, we are constantly searching for sustainable solutions.

The Group has a large proportion of fresh fish products in its product range – currently more than 80%. Approximately 70% of the products the Group sell are harvested or produced within the Group.

The UN Food and Agriculture Organization (FAO) has estimated that the world's population will increase to approx. 9 billion people by the year 2050.

A population growth of approx. 30% will require increased food production of approx. 30%,based on current food production volumes. The FAO has estimated that the increased demand for seafood will be in total 40 million tons by 2030.

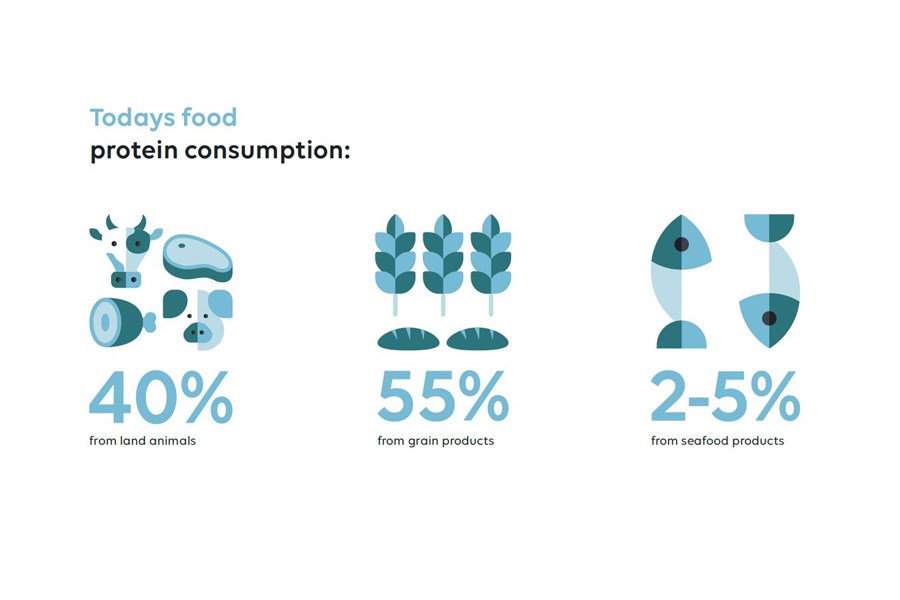

Today, less than 5% of the protein consumed worldwide originates from the sea. There is no doubt that we will need some source of protein in the future, making the potential for increased production of food from the sea particularly relevant.

Seafood is highly sustainable in a climate perspective for several reasons:

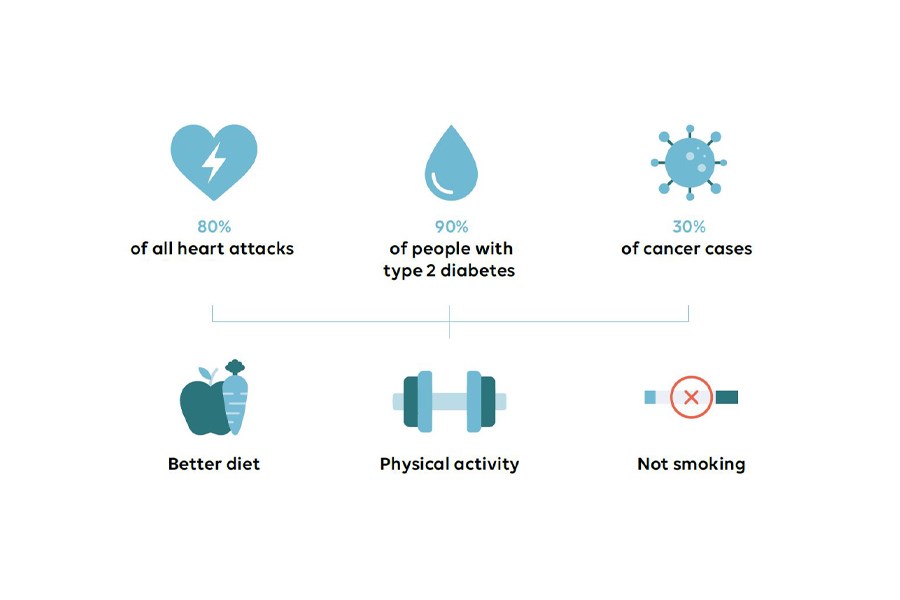

In 1999, 60% of all deaths and 43% of all illnesses were related to overweight, diabetes and osteoporosis. In 2025, these figures are expected to be 73% and 60% respectively.

Unhealthy diet can cause various types of illness. The lifestyle diseases now emerging in large parts of the world can be prevented by ensuring a correct diet. All dietary experts recommend that we eat more seafood and less red meat. We are in a unique position to contribute in this area. We therefore take an active role with our partners to encourage people to eat seafood, and to increase knowledge of, and access to, seafood in different arenas.

Recent consumer surveys have indicated a reduction in the consumption of seafood among children and young people. This can be a serious problem in the years to come if we cannot change this trend. An increased intake of seafood will help people improve their diets and will reduce the incidence of lifestyle diseases.

SEAFOOD IS GOOD FOR YOU!

Oily fish has a high Omega-3 content and a low Omega-6 content. We tend to focus on Omega-3 in our diets and forget Omega-6.

The World Health Organization (WHO) is concerned about the high consumption of Omega-6 in our diets, and recommends that we all reduce the amount of Omega-6 we eat. Seafood often has a high content of Vitamins A, E and D and is rich in the minerals zinc and iodine. Cod is a particularly good source of iodine.

Health authorities recommend that we eat more fish and reduce our consumption of red meat. Increased consumption of seafood has the potential to improve public health. It has been documented that salmon has a positive effect on preventing cardiovascular diseases, and several trails have shown a positive impact on preventing other diseases such as dementia, diabetes, depression etc.

Within the Group, there is a high focus on health – the health of our employees and of both current and future consumers. The individual human being, the consumer, is important both for the community and for us in the Group, as these are the people who will buy our products and therefore secure our jobs.

Surveillance of undesirable substances and fatty acid profile

As a result of the feed strategy in the Group and by using alternative resources in feed, we have reduced the level of undesirable substances such as dioxin and DL-PCBs in the salmon by 38% per cent from 2011 (0.736 pg/g) to 2019 (0.445 pg/g).

In the same period, we have managed to stabilize the level of EPA/DHA from 2011 (1.21 g/100g) to 2019 (1.17 g/100g).

Salt

In 2016 the Group made an agreement with Norwegian health authorities. The agreement obliges the parties to work towards reduction of salt.

Main Goal: Salt intake in Norway will be reduced by 15% by 2018, 20% by 2021 and 30% by 2025.

The salt partnership - "Saltpartnerskapet"

The goal of the salt partnership is to stimulate the food and catering industry to reduce the content of salt in foods and food served, as well as to increase awareness of salt and health in the population. Furthermore, dissemination of knowledge and competence, research, information to consumers and monitoring of the efforts are key tasks.

Key facts and figures

More than 3.1 billion people depend on fish for at least 20% of their total animal protein intake, and a further 1.3 billion people for 15% of animal protein intake.

Often undervalued and discarded parts of the fish, like the head, viscera and back-bone, make up 30-70% and are especially high in micronutrients.

Fish consumption has increased from 9 kg per capita in 1961 to over 20 kg per capita today.

The Group’s strategy is to meet the market’s ever increasing demands for food safety, quality, product range, cost efficiency and continuity of supply. This is achieved by coordinating the various elements in the value chain: the production units, the Group’s sales network, and established strategic alliances with sea farms, fishing vessels and fish-processing plants, primarily along the coast of Norway.

The Group is actively involved in all parts of the value chain in order to ensure supply of safe products to the consumer. Based on experience gained over many years, we have developed a quality system comprising routines and procedures to ensure supply of safe products.

As a part of the Group`s quality assurance routines, we carry out control and monitoring of our manufacturers and partners. This involves specifying requirements for their quality systems and routines, and carrying out analyses and monitoring operations.

Moreover, the products are controlled by Lerøy Seafood Group at different stages throughout the entire production process; from roe, boat and purchasing station to the finished and boxed product and, in certain cases, up to delivery to the customer.

For many years, the Group has followed a definitive strategy for quality assurance. Our strategy is that larger facilities and all facilities producing RTE, Ready to eat, products must obtain a GFSI food safety standard.

In the last year the Group has invested in a live microbiological reporting system. The system receives microbiological result directly form the laboratory. This system is beneficial in that we receive the results of microbiological test more quickly, and can implement more efficient actions if nonconformances should occur.

In 2020 Lerøy initiated a new way to measure food safety culture across the companies in the group. Food safety culture are defined as the food safety attitudes, beliefs, behaviour and values shared by all the employees in the company. The food safety robustness is essential in a company that produce safe and sustainable quality seafood.

Measurement of Food safety culture is combined with the yearly employee survey GPTW that Lerøy assess every year. The result of the survey will identify improvement areas for the food safety culture in each company and give the possibility to measure it against a bench mark for the Food safety culture in the group or within a specific segment in 2021. Each company must then put down an action plan how to improve or maintain a high food safety culture.

Link

Policy: Food safety

KPI: Certification

The Group invested in a new food safety surveillance programme in 2019 and have further developed this program in 2020.

The programme imports microbiological results from product samples, cleaning samples and environmental samples directly from the laboratory as soon as the results are ready. The processing facility receives the results immediately and the results are then visualized in the system automatically.

The microbiological results on equipment, direct & indirect surfaces and products are imported and visualised in a chart, making it easy to analyse trends and see where and when detections occur and take preventive action. To date, 15 processing facilities have implemented the system, and an additional facilities will be added in 2021

The system has enable us to take action on non-conformities early ensuring food safety on end products. One example is to block a fillet machine if Listeria monocytogenes is detected on the environmental surfaces before Listeria contaminate products.

The system also enable the Quality Department at the sales division to have live overview of microbiological status on all processing facilities and products

For farmed salmon and trout, information on brood stock, eggs, juvenile fish, growing, harvest and processing is available for customers online through the traceability programme, Fishtrack.

In Fishtrack, all information on feed, licenses, treatment and quality of the fish is available and linked to the customers invoice number. All this traceability information is open for customers and consumers at www.gladlaks.no

For whitefish and wild catches, information on fishing sub area, fishing gear, catch date, landing date, production date and processing facility is available.

The Group have launched a product traceability system on the customers Blockchain solution (IBM). Products with a full traceability, consumer facing QR code are now available for consumers in shops. The Group is working on a similar solution for whitefish products.

Link

KPI: Traceability

KPI: Product recall

The preparedness group for the Group consists of:

The core & responsible of the preparedness group comprises of the CEO and Head of Quality and Sustainability. The other members are invited to meetings depending on the items to be discussed – Farming, VAP/ Sales, Fisheries or processing. The preparedness group has primary responsibility, both internally and externally, for communications and handling of any relevant challenges/crises.

Preparedness plans are also drawn up locally. All facilities have a local preparedness group if a recall should be necessary. The preparedness group consists of persons representing all parts of the operations.

The typical procedure for product recall consists of the following phases:

Class I: Need for information

Class II: Other faults/nonconformances in the product

Class III: Products representing a health risk

5 Verify nonconformance, i.e with external expertise (lab)

Preparedness test/recalls of products

Every year the Group performs preparedness tests to verify that the traceability and recall system works correctly and efficiently, our recall procedure can be initiated and operated at any time. It is essential to train employees and improve preparedness procedures to be able to ensure an efficient recall regarding food safety if a real case should occur.

A preparedness test is a fictive case related to food safety, which includes: Processing facility, harvest facility, farming including juvenile stations, feed supplier, sub suppliers, the authority and customers. All actors must supply correct documented information. It is also checked if relevant key contact/ out of hours contact details are up to date and correct.

After a recall test, a summary is compiled by the preparedness group and improvement points are identified and implemented. A recall has a time limit of maximum 4 hours.

The Quality Manager at the production facility (QMP) together with the quality Manager at the sales department (QMS) are responsible to ensure that all recalls are carried out according to the procedure. QMP and QMS are also responsible involving correct personnel, external expertise and recover documentation required ( analytical reports, quality assurance log, traceability information etc).

In 2020, six preparedness tests were executed. No serious non-conformities were found, but four improvement suggestions/corrective actions where identified related to more efficient collection of data and more personal with this information available.

Link

KPI:Product recall

Policy: Food safety

Recall

A recall is when a product with defects that violate food safety, have reached the end consumer and is removed from the marked. A withdrawal is product with the same characteristic but are removed in the supply chain before it has reached the consumer.

In 2020 the group had 0 recalls of Lerøy products and 3 withdrawals. All three withdrawals was mistake in the labelling, wrong/too long use by date. The root cause of these withdrawals was human error when manual registration the date formats in the label system. This has been rectified so date formats now is tranferred electronically from ERP system to printer removing the possibility for human errors.

Link

KPI: Product recall

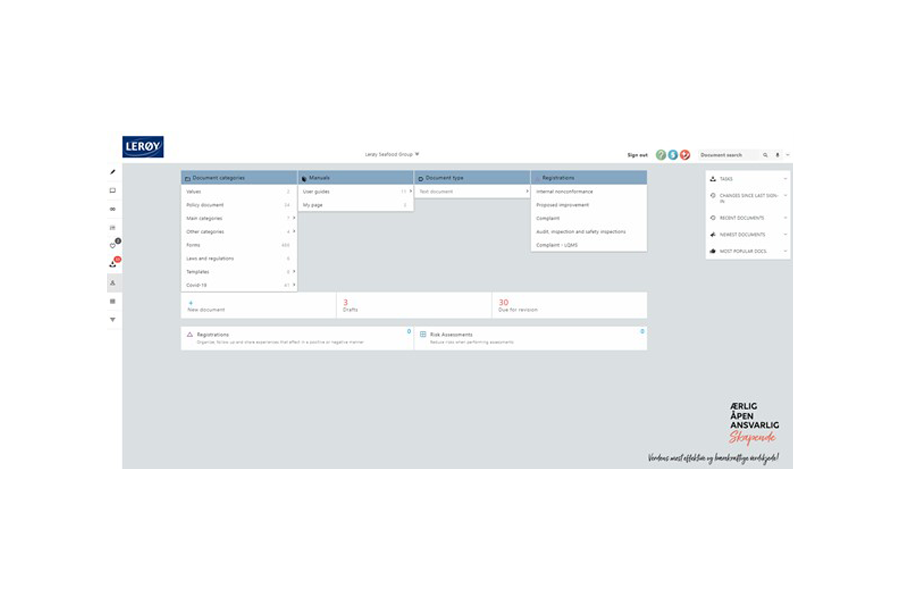

All the companies within the Group use the same quality system: Lerøy Quality Management system (Lerøy QMS).

The system enable us to share procedures and instruction across companies, register controls and audits, send improvements, non-conformities and corrective actions electronically across companies and make common risk analysis of operations.

The system helps Lerøy to work as one, as it is a tool too share knowledge and improvements across and between companies in the group. Lerøy QMS also enable us to report as a group on ESG.

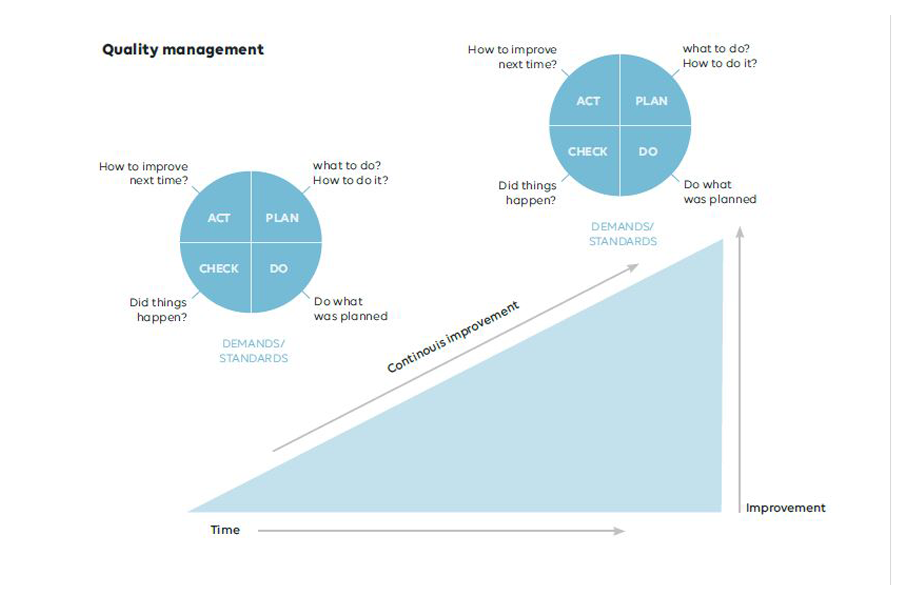

Lerøy Seafood Group is continuously seeking to identify improvements which may reduce our environmental impact and sustain our food safety culture. As a part of the effort to verify the hard work to improve the environmental and social impact of seafood production, Lerøy has gained certification according to international environmental and social standards.

As a part of the Group’s programme for continuous improvement and preventive action, the Group conducted in total 593 documented audits and inspection events in 2020. These includes 222 internal food safety audits and 371 audits and inspections performed by a third party (certification bodies, authorities) and internal audits (safety inspection, internal audits, supplier audits).

These audits resulted in 2640 related incidents (non-conformities, observations and improvements suggestions) leading to corrective actions. All related incidents were closed within time limit. All processing facilities follows a food safety audit rotation plan covering all important aspects of the production, minimum quarterly. In addition food safety quality controls are performed daily on each batch.

Corrective action rate is the number of corrective action plans completed in accordance with the relevant GFSI scheme, no later than 30 days from the audit date, to address major non-conformances, divided by the total number of major non-conformances that have been identified. In 2020 no Lerøy facilities received GFSI fundamental, critical or major nonconformities, so the correction action rate i 0. All minor non conformities where rectified and closed within time limit. BRC certification grade for the processing facilities ranges from AA to B.

Internal audits, supplier audits and certification, audits are an important area for continuous improvement and training. The Group’s strategy is to increase the levels of internal audits in the years to come, and also to make use of new technology to do so.

✔️Food safety

✔️High quality

✔️Identify improvements

✔️Reduce our environmental impact

✔️Sustain our food safety culture

✔️Gain certification

Certifications

The Group is a corporation involved in global business and working relationships with more than 6000 direct suppliers worldwide.

We have worked closely with several of our suppliers for decades, they are all familiar with our requirements.

As a Group we are aware of our responsibility to control that our supplier; follow our code of conduct; have goals and work towards lower emissions; have strategy and routines for HSE; have an GFSI certification or working towards and GFSI certification (Food safety)

To take responsibility for working with continuous improvement with all our suppliers, the Group has developed a supply chain management system.

The system gives us:

The pilot phase of the system have now been finalized Lerøy and are launched in 2021.

Link

Policy: Procurement

KPI: Supplier evaluation

In August 2014, Russia decided to ban the import of Norwegian seafood in response to sanctions imposed by the US, the EU and others for the annexation of Crimea. Lerøy is working together with our customer towards the authorities to solve the ban. Financial cost of the ban is unsure.

The product development department is located at the Group’s Headquarter in Bergen. The “One Lerøy product development team” works through the entire value chain, from the raw materials to finished products in stores.

Every year, a variety of products are developed in different product groups adapted to different segments. The department cooperates with production and sales to achieve the requested products.

The Group's products are frequently nominated for prizes in various media/ innovation areas, and have won several awards. The Group has sustained its positive trend within product development in previous years, with the launch of a number of innovative products and new product types, mainly within freshly packaged fish.

The Group also continues to develop its “fish-cut” concept in many parts of Europe. These processing units follow a target-driven and efficient strategy, focusing on freshness, a high level of service and proximity to end customer.

The product development department have a strong fucus utilize 100% of the raw material. Products should give the consumer a healthy experience well balanced with natural ingrediencies and low salt content. The goal is to give consumers a better and more healthy way of eating

Lerøy is committed to work towards a sustainable packaging material portfolio within 2030 for all products. This entails using packaging materials that reduce food waste, prolong shelf life and product quality in addition to having the lowest possible eco footprint.

To achieve our goal we are reliant on working together with our customers, our suppliers and regulatory bodies to transition from the use of non-recyclable/biodegradable packaging materials, to materials which can either be recycled, reused or is bio degradable. In addition we need to help ensure that the infrastructure for recycling/reuse is sufficient to handle the quantity used.

There are several reasons why good sustainable packaging solutions are important for Lerøy and our customers. First of all our products needs to reach its destination safely without compromising the products food safety and product quality. Secondly we need to ensure that we do this as economically as possibly so that we can offer our products at a competitive price. This means that the packaging not only needs to be priced correctly, but it also needs to be within our specifications when it comes to weight, durability, recyclability and composition. Thirdly the packaging material needs to fit into our sustainability strategy and fulfilling all regulations and industry standards. We need to make sure that our choices is sustainable and at the same time not compromising food safety.

To ensure that all companies in the group work towards the same objectives we have established a category team for packaging. The team work closely with not only our own companies and suppliers/producers, but also other aquaculture companies and NGO`s to make sure that the best packaging solutions are always used. The team is comprised of people from different departments in Lerøy with different knowledge and experience to ensure that we make the right decisions for our customers, and the environment.

Lerøy have set a target to reduce the use of plastic in the Group by 50 % within 5 years (Base year 2019). Packaging materials is one of the categories we have targeted to be a contributor to reaching this target. To be able to reach this target we have had to challenge all our suppliers of materials containing plastic. In the past 2 years we have had several workshops and meeting with suppliers to find alternative packaging materials, reducing the volume of plastic used, and discussions regarding different R&D projects.

We have done several tests to see if we could find alternative materials, which have the same properties as plastic (does not compromise on food safety). Testing is still ongoing, and we hope to have a clearer overview of possible alternatives for some the product groups within 2022.

The Group is looking into the possibility to use packaging made of organic materials from the sea. The hope is to wrap the seafood in organic material from the sea which is bio degradable.